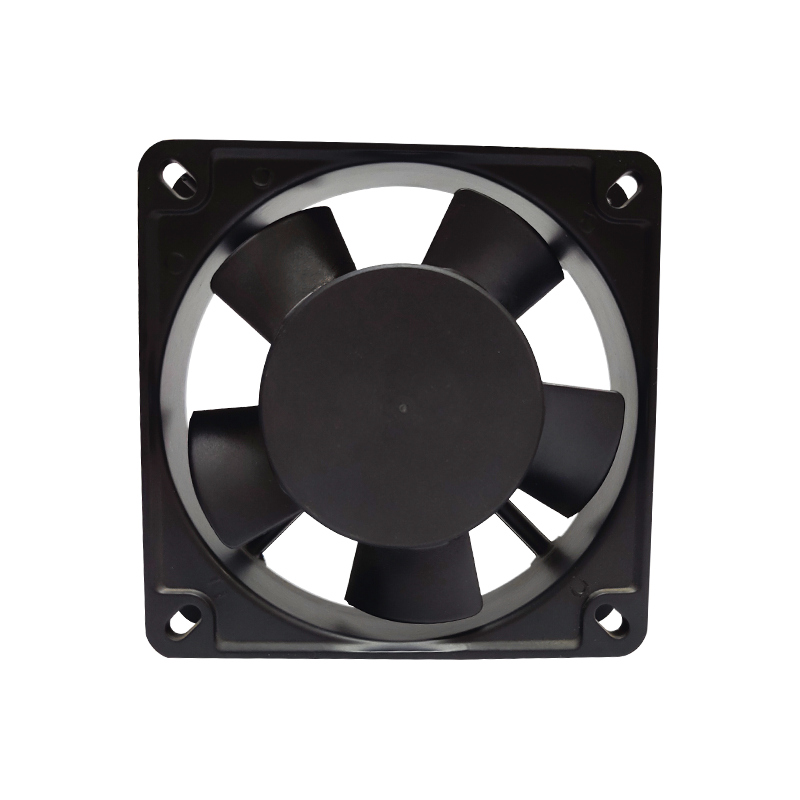

How to use and select AC/DC fan lubricating grease (such as PLS-2 oil)? What is its function?

Our company has strong technical force and advanced equipment, and has accumulated rich experience and technical advantages in the field of electronic component manufacturing. Especially in terms of the use and selection of lubricating grease for AC/DC fans, we are able to provide professional and in-depth technical guidance based on our mastery of high-precision slitting and winding equipment, production lines and sophisticated testing equipment.

AC/DC fan grease plays a vital role in the operation of the fan. Specifically, it mainly has the following functions:

Lubrication and anti-friction: Lubricating grease can form a protective oil film on the rotating parts of the fan shaft core and sleeve, separating the surfaces of relatively sliding parts, significantly reducing wear and extending the service life of the fan.

Cooling and cooling: Lubricating grease can effectively absorb and take away the heat generated by friction, assist the fan in maintaining normal operating temperature, and prevent performance degradation or damage caused by overheating.

Sealing and leak-proof: Good adhesion enables the grease to fit tightly between the shaft and the shaft hole, forming an effective sealing layer, reducing grease splash and leakage, and keeping the inside of the fan clean and lubricated.

Anti-rust and anti-corrosion: Lubricating grease can adhere to the surface of parts and form a protective film to isolate water, air and other corrosive substances and prevent parts from rusting and corroding.

Noise reduction: High-quality lubricating grease can significantly reduce the noise of the fan during operation and improve the overall quality of the product.

When selecting AC/DC fan grease, there are several key factors to consider:

Type of base oil: Different base oils have different lubrication properties and service life. Our company recommends choosing a compound base oil with high purity and high viscosity coefficient, such as grease with a viscosity coefficient exceeding 260, to ensure good lubrication effect and stability.

Additives: High-quality lubricating grease will add various additives such as anti-rust, anti-oxidation, anti-wear and PTFE to improve the overall performance of the grease. These additives can enhance the lubricity, anti-wear and corrosion resistance of the grease and extend the service life of the fan.

Volatility and stability: In high temperature or long-term constant temperature environments, lubricating grease should maintain low volatility to maintain its excellent lubrication performance. The grease selected by our company has the characteristics of non-spreading and non-leakage under high temperature conditions. It is not easy to deposit carbon during long-term use and can effectively maintain the amount of lubricating oil between the shaft and the sleeve for a long time.

Applicability: Select the appropriate lubricating grease according to the specific model, power and usage environment of the fan. Different fans may have different requirements for lubricating grease, so the selection needs to be based on the actual situation.

When using AC/DC fan lubricating grease, you need to pay attention to the following tips:

Clean the fan: Before adding lubricating grease, you need to clean the fan shaft core and sleeve to remove dirt and old grease on the surface to ensure that the new grease can fully function.

Add appropriate amount: When adding lubricating grease, control the amount. Too little may result in insufficient lubrication, while too much may cause grease to overflow, affecting the normal operation of the fan. Generally speaking, just add an appropriate amount according to the specific model and specifications of the fan.

Evenly apply: Apply lubricating grease evenly to the rotating parts of the shaft core and sleeve to ensure that the grease can fully cover and penetrate into each lubrication point. This can be done using a special applicator tool or a cotton swab.

Regular replacement: Lubricating grease may deteriorate or become ineffective after being used for a period of time, so it needs to be replaced regularly. Our company recommends replacing the lubricating grease every six months to one year based on the frequency of use of the fan and the working environment to keep the fan in good operating condition.

As a professional capacitor manufacturer and air conditioner and refrigerator accessories agent, our company not only has strong technical strength and advanced production equipment, but also has a complete testing system and a rich product line. We are committed to providing customers with one-stop purchasing services to meet their diverse needs for capacitors, air conditioners, refrigerators, washing machines and other accessories. At the same time, our employees face the market directly and can more agilely and quickly obtain and meet the fragmented and personalized needs of customers. In terms of the selection and use of AC/DC fan lubricating grease, we are also able to provide professional technical support and solutions to ensure that customers' equipment can operate stably and extend its service life.

The selection and use of AC/DC fan lubricating grease has an important impact on the performance and life of the fan. With strong technical strength and rich experience, our company is able to provide customers with professional lubricating grease selection and usage guidance to ensure that customers' equipment can operate stably and perform at its best.

English

English Français

Français Español

Español عربى

عربى